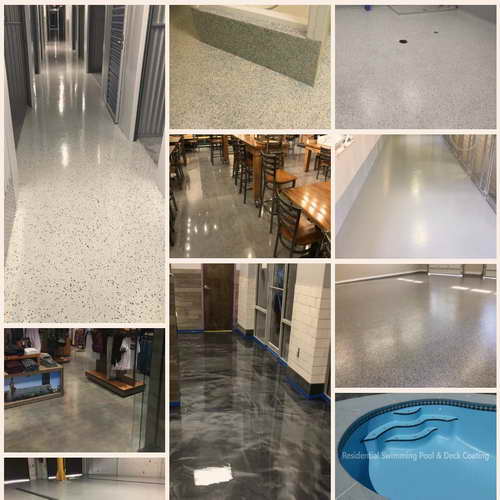

Concrete Polishing Services

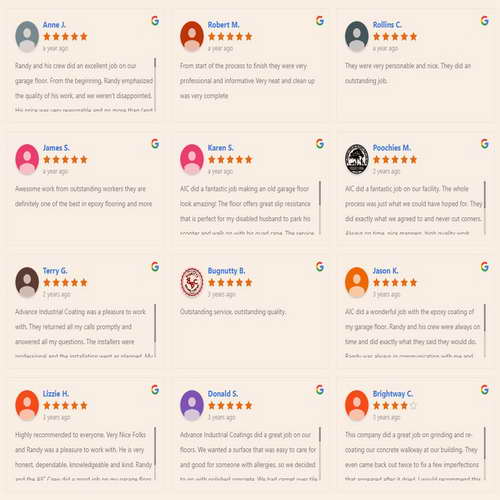

We are your local Polished Concrete expert serving Jacksonville, Orlando, Gainesville Florida and many other cities in North and Central Florida for over 30 years with the highest integrity and workmanship standards!

We are specialized in installing attractive and high quality Concrete Polishing, Concrete Dying, Concrete Staining, and Concrete Sealing flooring systems for Industrial, Commercial & Residential customers. Advance Industrial Coatings offers different types of flooring systems, products lines and solutions to meet your special application environment needs.

We also offer Polished Concrete Maintenance Programs tailored to meet each customer’s long-term concrete polishing maintenance needs. Advance Industrial Coatings’ polished concrete maintenance programs range from Full-Service Solutions to Self-Service with Support Programs.

Concrete Polishing Services

More retail, restaurant, warehouse, fleet management and office facilities are opting for polished concrete flooring as an alternative to marble, granite, tile, vct, wood, linoleum, or coated concrete. Even homeowners are catching on to the appeal of these smooth, high-luster floors, which can be stained to replicate the look of polished stone.

What is Polished Concrete?

Polished concrete is concrete that has been processed through a series of mechanically ground “polishing/grinding” steps utilizing professional equipment designed for concrete polishing. This process also includes the use of concrete densifier/hardener which penetrates into the concrete and creates a chemical reaction to help harden and dust proof the surface. During our Concrete Polishing Services, the concrete substrate surface is processed through a series of steps (in general a minimum of 6-8 grinding steps of processing is considered polished concrete) utilizing progressively finer grinding tools. The grinding tools are progressive grits of industrial diamonds in a bonded material such as metal/hybrid/resin often referred to as diamond polishing pads.

Concrete is not considered polished before 800 grit, and it is normally finished to either the 800, 1500, or 3000 grit level. Dyes designed for concrete polishing are often applied to add color to polished concrete as well as other options such as scoring, creating radial lines, grids, bands, borders, and other designs.

Why Choose Polished Concrete Flooring?

Simply put, our concrete polishing services transforms a porous concrete floor into a tightened surface, dense enough to keep water, oil, and other contaminants from penetrating the surface.

Elegance and Attractive

Very Strong and Durable

Less Maintenance

Extended Long Life-Span

Highly Cost Effective

Hygiene Friendly

Minimum Downtime

Better Ambient Lighting

HOW CAN WE HELP?

Contact Us Today for a FREE Consultation, Inspection and Cost Estimate.

We are committed to protecting your privacy & personal data. Read our Privacy Policy.

Dyed Concrete

Dyed Concrete are the latest buzz in the decorative concrete community. Concrete Dyes can be defined as a coloring material for imparting a particular hue to a surface. Dyes are a great way to color existing slabs of concrete. Their ease of use, extensive palette, and vibrancy of color (which can be more intense than chemical stains) are creating a wave of popularity that is gaining momentum.

The raw form of a dye is a super fine powder that can be dispersed in a solvent or water. Typical concrete dyes are not UV stable. Some special ‘exterior dyes’ or pigments come in vibrant colors as well and are UV stable.”

Unlike stains, which react chemically with the calcium hydroxide in concrete, dyes are non-reactive and impart color by penetrating concrete or other porous cementitious surfaces. Dyes are much smaller in particle size than chemical stains or acrylic stains, thus allowing for easier penetration and color saturation while leaving less residue on the surface.

The system is highly customizable with an extensive color palette and variable application thicknesses. Final surface options include: integral cove base, and variable surface texture to produce a range of slip-resistant finishes.

Stained Concrete

Stained concrete has a unique beauty that’s brought to life by different finishing and coloring techniques. There’s no predetermined color palette to limit designs.

Acid-based concrete stains are made up of inorganic metallic salts dissolved in an acid and water solution. They penetrate into the surface and react chemically with the concrete to form a permanent bond. Rather than produce a solid, cloudy effect like paint, stains permeate the concrete to fill it with luminous, translucent tones. The finish color is related to the substrate they are applied to and the application methods used.

Sealed Concrete

A concrete floor sealer will enhance and protect your floor. No decorative concrete floor installation is complete without the application of a sealer. Sealing brings out the beauty of a concrete floor by enhancing the color and adding sheen. Sealing also preserves the decorative treatment by protecting the floor surface from abrasions and stains. Some floor sealers form a protective film on the surface of the concrete, while others penetrate into the floor.

Sealed Concrete is also called “Grind and Seal Flooring“, which is a term used for the system of applying a clear, protective coating to diamond grinded concrete floors.

The grinding refers to the removal of any impurities or scratches in the substrate surface layer. This is completed using special concrete grinders that quickly and efficiently remove existing surface materials, open concrete pores and create enough surface profile.

After grinding, a clear, or colored concrete sealer is applied to protect the concrete. These sealing coats are usually made of epoxy, acrylic, or urethane.

Although this process is commonly referred to as “polished concrete,” there is a big difference between “grind and seal” and “grind and polish.” Polished Concrete is hardened with a densifier and refined to a much higher level to create the shine. This densifier then reacts to the cement to harden the top layers. It’s then sealed with a polish guard sealer to avoid any water, bacteria, or stains. Polished Concrete systems tend to be more expensive but more durable.

Polished Concrete Maintenance Programs

Full-Service Polished Concrete Maintenance Program

Under an annual/monthly fixed-price agreement, Advance Industrial Coatings is fully responsible to maintain polished concrete floors to the predetermined, quantifiable gloss levels. We bear the risk that any given floor may need more maintenance than anticipated. Customers are guaranteed their concrete polishing floors never drop below a predetermined level of acceptability at a set price.

- Full-Service polished concrete maintenance program – customers trust us to take care of everything so they don’t have to worry about it at all

- Guaranteed consistent appearance

- Fixed price contract with no additional charges

- We take ownership of floor & bears risk for additional costs

Monthly Service Polished Concrete Maintenance Program

Advance Industrial Coatings works with its customers to develop a long-term polished concrete maintenance plan to meet customers’ specific needs, expectations and budgets. As part of the maintenance plan, a long-term schedule is created whereby AI Coating crews perform a fixed amount of polished concrete floor maintenance procedures at specific intervals.

- Proven programs with reliable, predictable results

- Cost effective

- Flexible options available to address specific concerns

- Extra service visits available to meet specific needs at additional costs

In-House Service with Support Polished Concrete Maintenance Program

This is a concrete polishing maintenance program utilizing existing facilities maintenance personnel and equipment to meet specific needs, expectations and budgetary concerns. To the extent necessary, Advance Industrial Coatings will spec and provide equipment, polished concrete cleaning supplies, densifiers, stain guards as well as burnishing and polishing pads. Technical and field support is provided upon request. Periodic monitoring and evaluation options are available.

- Leverages in house personnel and equipment with our expertise

- Customer retains control of maintenance procedures

- Customer reassured by AI Coating support

- Lowest cost