Concrete is a popular building material. It’s most commonly used for flooring, sidewalks, and patios, but it can be used in many other capacities, too. Concrete’s popularity is due mostly to its cost, versatility, and durability. However, when it comes to concrete, there’s no shortage of advantages.

The most significant misconception people have about concrete is that it’s all the same. That there’s one type of concrete, and that’s it. However, that’s just not the case. Concrete has many different make-ups, finishes, sealers, and polishes that can all dramatically impact its performance and design.

Let’s get into all the complexities of concrete and weigh the performance of all the options.

What Is Concrete?

Many people use the words “cement” and “concrete” interchangeably. However, concrete and cement are not synonymous. Concrete is typically made from three primary components. These components are aggregate (sand and rock), Portland cement, and water.

Cement is a primary ingredient of concrete. Portland cement is the most popular type of cement. However, it’s not the only option. Today, there are many cement alternatives. These alternatives include:

- GGBS (ground blast-furnace slag), created from the waste of steel and iron manufacturing plants

- PFA (pulverized fuel ash), created from coal-burning power stations

- Silica Fume, created from the production of silicon

The benefits to these three examples are that they are more environmentally conscious alternatives to traditional Portland cement. They use byproduct and waste from manufacturing plants, rather than using raw materials.

In addition to these more environmentally-friendly cement alternatives, several companies have introduced heat and chemical resistant concrete. These concrete types all use a variety of different kinds of cement, but their function is the same. By combining different techniques and materials, some companies have found a way to make concrete more heat and chemical resistant than standard concrete.

When it comes to choosing concrete and cement, you have to weigh a few options. Traditional Portland cement concrete will be the most cost-effective solution. Some of the eco-friendly alternatives are worth considering if you want to lower your carbon footprint. However, if you’re going for maximum performance, your best bet is to go with a resistant concrete from the start.

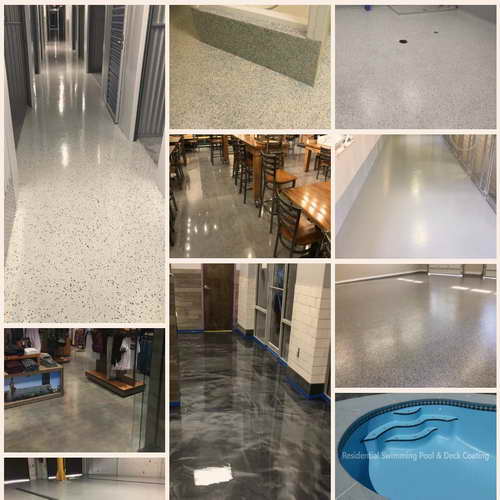

Concrete Finishes

Concrete and cement types aside, there are several different concrete finishes. These finishes aren’t to be confused with sealers or polishes, which will talk about in a minute. Finishes have more to do with how the concrete is laid.

These are three popular finishes:

- Stamped Concrete

- Slick Troweled Concrete

- Broom Finished Concrete

Stamped concrete is typically for residential properties. The concrete is laid and then stamped with a rubber mat to add texture and designs. These designs are generally done so that the concrete mimics the look of natural stone, brick, or other materials.

Slick troweled concrete is the style that’s usually found in warehouses, basement and garage floors, and front porches. This finish requires a machine or steel hand trowel to lay. The benefit of this type of concrete is that it’s a breeze to clean and maintain. The downside is that it can be slippery when it’s wet or dirty.

Broom finished concrete is concrete with a rougher texture. It’s created by running a broom attachment over the surface of the concrete while it’s drying. The benefit of this type is that there’s more traction. Therefore there’s less of a danger of slipping when it’s wet or dirty. However, it can be challenging to clean because of the rough finish.

Ultimately, the finish you choose will be based on your unique needs and priorities. If easy maintenance is a high priority, go with slick troweled concrete. If accident prevention is a priority, go with broom finished concrete. If you want something that looks great and is highly resistant, go with an epoxy coating. If you want your concrete to look like something other than concrete, then stamped concrete is the way to go.

Concrete Sealers

One of the only downsides to concrete is that it’s incredibly porous. Because of this, you must seal it. Concrete sealers block out moisture while keeping your concrete protected. However, not all sealers are created equally.

There are a few different types of concrete sealers. These are some of the top choices:

- Acrylic Sealers: Acrylic sealers are cheap and last anywhere from one to three years. They’re easy to apply and give the concrete a glossy look. They also quickly dry, which can be great if you want a quick turnaround. They help block out moisture and grime and keep your concrete protected. The major downside is how frequently they need to be reapplied.

- Epoxy Sealers: Epoxy sealers are longer lasting and harder than the acrylic alternative. This type of concrete sealer lasts around five to ten years. Like the acrylic sealers, epoxy sealers leave a glossy finish. Colors and anti-slip additives can easily be added to an epoxy finish, too. They resist water and stand up well to foot traffic. Epoxy sealers are mostly used on countertops and indoor stained concrete floors.

- Penetrating Sealers: Penetrating sealers are the most durable and long-lasting of all the sealers. Once applied, this type of concrete sealer can last ten years or more. They’re the most resistant to moisture. In fact, you can pour liquid directly onto the floor, and it will bead up. This sealer protects against moisture, erosion, staining, UV rays, and inclement weather and temperatures. Unlike the other two mentioned, penetrating sealers don’t leave a glossy finish.

If you’re going for maximum performance, penetrating sealers is the way to go. However, if you want the most cost-effective option, then you might prefer acrylic sealers instead.

Concrete Comparison: Picking the Winner

There are many choices when it comes to concrete. And it doesn’t end there. Now, there are polishes, paints, and designs to consider, too. These final touches can dramatically change the look of concrete.

There are many choices when it comes to concrete. And it doesn’t end there. Now, there are polishes, paints, and designs to consider, too. These final touches can dramatically change the look of concrete.

Ultimately, picking the cement, finish, sealer, and overall look comes down to preference and priorities. If you’re strictly going on performance, a heat-resistance concrete, with a slick troweled finish, sealed with a penetrating sealer is the way to go. If you want to focus on the design it may be worth it to look into polishing your concrete, one thing to keep in mind with polishing is that when focusing on the concrete substrate layer of concrete the hardness of the surface is an important factor to keep in mind. However, cost is also a crucial factor to consider. Where your concrete is going is another.

Consider your needs and go with the concrete choices that best fit the bill. In the end, you’ll still end up with one of the most popular building materials out there.

Matt Lee is the owner of the Innovative Building Materials blog and a content writer for the building materials industry. He is focused on helping fellow homeowners, contractors, and architects discover materials and methods of construction that save money, improve energy efficiency, and increase property value.